Imagine waking up one morning and brushing your teeth. However, when you turn on the basin tap to rinse your mouth, you find that the pipes have clogged, and there is barely any water dripping from the tap. You try to repair it but find that the joints have rusted.

It is an unfavorable situation since now you do not know how to start your day. Now, you are standing near your basin sink with foam in your mouth, still trying to fix the tap, as your boss sends in a warning for absence.

You might have avoided the entire situation if you had committed to minor preventive maintenance in the past. So, what is preventive maintenance anyway?

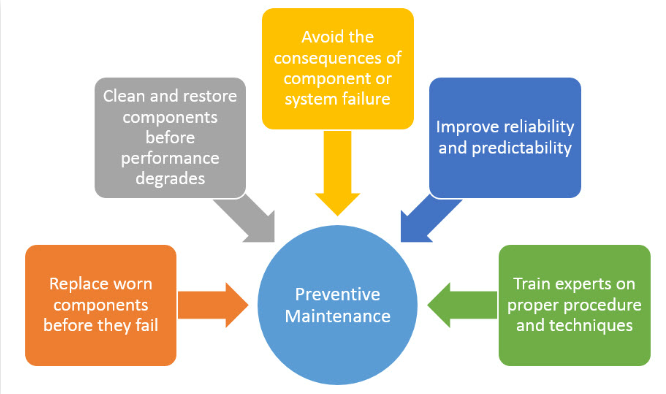

A preventive maintenance is a defensive mechanism to protect your assets from damage and downtime. It involves predicting or scheduling maintenance tasks well ahead of any cases of breakdown. However, preventive maintenance is not an easy task; it requires a lot of careful planning.

It involves understanding the workplace’s different assets, analyzing and delegating maintenance tasks and crew, and maintaining a smooth workflow. A maintenance plan takes care of all the assets and maintenance time, along with other vital parameters. Hence, it is not easy to create a maintenance plan.

Contents

How to Create a Preventive Maintenance Plan That Values Assets

At some point, businesses realize that the breakdown of equipment and assets hampers productivity and efficiency. If your organization plans to build up a preventive maintenance plan to value your assets, the following tips may be useful.

Build an Asset List

The first thing you need to do is create a list of all the facility assets that require maintenance. You need to know the number of assets, their location, and the assets’ condition to build a proper preventive maintenance program. It should also include the specifications and detailed instructions to maintain every asset.

You can also arrange assets on their importance to company productivity. It will help you formulate the most important assets you need to ensure it stays in operation.

Asset Assessment

Unless you understand the asset’s condition, have an accurate estimate of its hours of operation, and the expected lifetime of the equipment, you will not be able to create a preventive maintenance program. Additionally, you also need to keep track of hours of service history to perform maintenance later on.

While analyzing the assets, it is necessary to ask the following questions.

- What are the resources that are required to undergo maintenance?

- Is it better to buy a new model or maintain the equipment?

- Do the assets pose any safety hazards?

- Are spares of the equipment still available in production?

Look For Troubleshooting Signs

You may have a standard operating procedure for your maintenance tasks on a particular asset. However, many times, the equipment starts to show you signs that it needs maintenance and repairs.

For example, if a water pump starts to make an awful lot of noise, you should know that something is amiss, and look at the problem and troubleshoot errors.

You can avoid many problems through regular checkups of the assets and keeping an eye for signs. Usually, the maintenance task may be just as simple as applying a lubricant or coolant. However, if you avoid it at the time, it could hamper your machinery and assets.

Create a Checklist and Schedule

It is common for humans to forget a lot of preventive maintenance tasks. You may remember them later. However, a failure may occur in the assets due to one small part of the equipment.

If you create a checklist of all the maintenance tasks you need to perform, you will not miss out on any steps. Additionally, it will also help you make separate schedules for the tasks, such as daily investigation, weekly maintenance, or preventive maintenance over a more extended period.

Measure Asset Performance to Increase Efficiency

You must understand if the maintenance program in effect helps resolve current problems and whether it is boosting productivity and eliminating costs. You can set specific parameters for measuring asset performance. However, they need to be numerical to understand if the maintenance is providing positive results.

If the program is performing weakly, you need to analyze its reasons and come up with a better preventive maintenance program. Make sure that the maintenance is helping production and not stripping away hours of operation.

Use a Centralized Database

A centralized database, also known as a CMMS, tracks assets and maintenance crew and provides all the information under one platform.

Since everyone can view the database, it promotes transparency in the organization and helps to understand the maintenance task completion status and pending work.

It can help in delegating maintenance tasks to individuals who have completed their work to ensure that no maintenance tasks are pending.

Benefits of Using a Preventive Maintenance Program to Value Assets

Manages a Mammoth Task

A facility maintenance can be a daunting task with numerous assets. If anyone tries to carry out maintenance without a plan, it can only be breakdown maintenance. The breakdown of a single asset can have a heavy impact on productivity.

Hence, a preventive maintenance plan helps to save costs while promoting better asset management.

Repair Work Over a New Product

A new product can cost a lot of money. However, if you undergo preventive maintenance and provide repairs to the equipment, you can increase its estimated life. It will eliminate your need to purchase a new product altogether.

Hence, you will be saving a lot of money in the long run.

Eliminating Downtime

In any industry, downtime ruins the momentum of workflow, in addition to the hours of operation you miss from production. A Preventive maintenance program effectively removes this idle time so that you have a continually working facility that churns everything into valuable output.

Conclusion

A Preventive Maintenance Program keeps all assets in desirable working conditions and eliminates risks so that you can reap the benefits of the well-oiled machine. Productivity and preventive maintenance go hand in hand. It helps you to understand the value of assets and maintain them to perfect health.